Production CNC Machining: Transforming Metal Fabrication for the Modern Age

In the evolving landscape of manufacturing, production CNC machining stands as a cornerstone technology that enables precision, efficiency, and high-volume output. As industries demand increasingly complex and precise components, the importance of sophisticated CNC processes continues to grow, revolutionizing the way metal fabricators operate globally.

Understanding Production CNC Machining: The Foundation of Modern Metal Fabrication

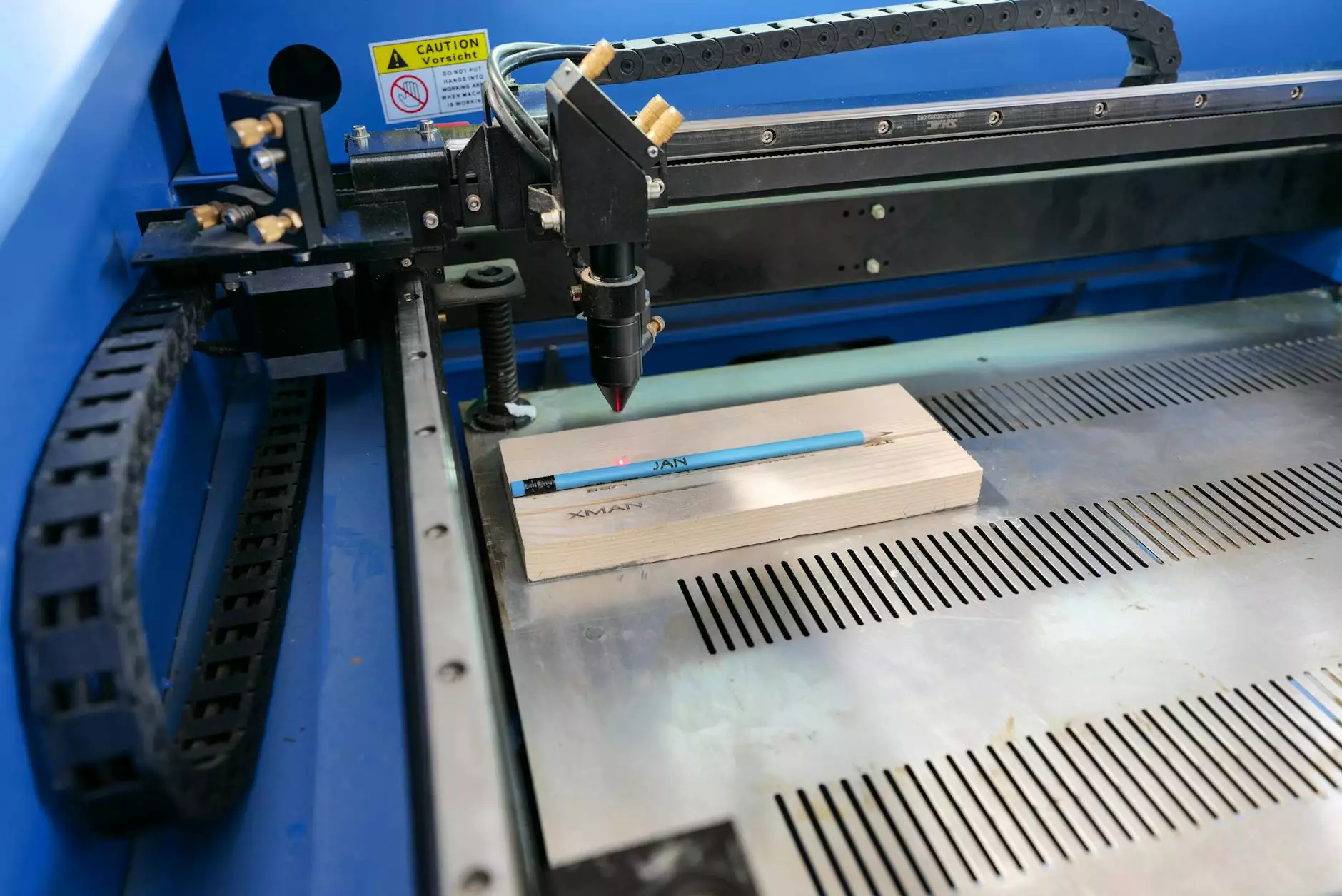

Computer Numerical Control (CNC) machining is an automated manufacturing process that utilizes computer-controlled machine tools to produce complex parts with unparalleled accuracy and consistency. The term production CNC machining specifically refers to high-volume, repeatable manufacturing processes tailored for the mass production of metal components.

At its core, CNC machining combines traditional machining techniques with modern automation, allowing manufacturers to achieve productivity levels that manual methods cannot match. This blending of technology empowers metal fabricators to meet tight tolerances, reduce waste, and accelerate production timelines.

The Role of Production CNC Machining in Metal Fabrication Industry

Enhancing Precision and Quality

One of the primary advantages of production CNC machining is its ability to deliver high precision and exceptional quality. Advanced CNC machines operate with tolerances often measured in microns, ensuring each component meets strict specifications. This is vital for sectors such as aerospace, automotive, medical devices, and electronics, where accuracy directly impacts safety and functionality.

Achieving High Efficiency and Throughput

With automation and sophisticated programming, production CNC machining dramatically increases throughput. Machining centers can operate around the clock, minimizing downtime through features like tool changers, multi-axis capabilities, and automated loading/unloading systems. This scalability makes it ideal for large-scale manufacturing requirements.

Cost Reduction and Material Optimization

By automating complex tasks, CNC machining reduces labor costs and material waste. Precise machining permits optimized material usage, which further cuts expenses. Over time, the integration of production CNC machining results in significant cost savings, making it a preferred choice for cost-conscious, high-volume productions.

Key Components and Technologies Driving Production CNC Machining

- Multi-axis Machining Centers: Providing superior flexibility and ability to craft intricate geometries in fewer setups.

- High-Speed Tooling: Enabling rapid material removal and smooth surface finishes for complex parts.

- Automation Systems: Featuring robotic loaders, automated tool changers, and conveyor systems to maximize continuous operation.

- Advanced Software: CAD/CAM integration ensures detailed customization, error reduction, and seamless programming.

- Material Diversity: Capable of machining a wide variety of metals including aluminum, steel, titanium, copper, and nickel alloys.

Why Industry Leaders Choose DeepMould for Production CNC Machining

As part of its commitment to excellence, DeepMould.net offers industry-leading production CNC machining services within the metal fabricators category. Their cutting-edge facilities are equipped with the latest technology, ensuring clients receive products that meet the highest standards of precision and quality.

DeepMould's approach emphasizes custom solutions, leveraging extensive experience in creating complex metal components. Their focus on automation, efficient workflow, and quality assurance guarantees that every project is delivered on time, within budget, and to exact specifications.

The Advantages of Partnering with Experienced Metal Fabricators like DeepMould

- Unmatched Precision: Use of the latest CNC machinery ensures parts are manufactured with tight tolerances, critical for high-stakes industries.

- Rapid Turnaround: State-of-the-art automation allows for swift production cycles, crucial for meeting tight deadlines.

- Cost-Effective Manufacturing: Economies of scale in production CNC machining reduce costs per unit without sacrificing quality.

- Flexibility and Customization: Capabilities to handle a wide array of metal types and complex geometries, supporting diverse client needs.

- Comprehensive Quality Control: Stringent inspection protocols, including CMM testing and in-process checks, ensure each component adheres to specifications.

The Future of Production CNC Machining in Metal Fabrication

The trajectory of production CNC machining is upward, driven by technological advancements like AI integration, smart sensors, and predictive maintenance. These innovations are set to further enhance productivity, reduce downtime, and improve quality control.

Moreover, the growth of additive manufacturing (3D printing) alongside CNC processes is paving the way for hybrid manufacturing techniques. This synergy allows for faster prototyping, complex geometries, and material efficiencies, further revolutionizing metal fabrication capabilities.

Designing for Manufacturing with CNC: Best Practices

- Complex Geometry Simplification: While CNC can handle intricate designs, optimizing geometry for manufacturability reduces cycle times and costs.

- Tolerance Alignment: Understanding the limits of CNC machining ensures realistic, achievable specifications.

- Material Selection: Choosing the right metal for durability, machinability, and application requirements benefits long-term performance.

- Surface Finish Requirements: Clear specifications on surface roughness help in selecting appropriate tooling and process parameters.

- Assembly Considerations: Designing parts with assembly in mind improves overall efficiency and reduces post-processing time.

Conclusion: Choosing the Right Partner for Your Production CNC Machining Needs

In today’s competitive manufacturing environment, production CNC machining is not just an option but a necessity for businesses aiming for precision, scalability, and cost efficiency. The right metal fabricator, equipped with cutting-edge technology and industry expertise, can significantly influence your product’s quality and time-to-market.

DeepMould.net exemplifies this ideal, providing comprehensive production CNC machining services tailored to meet the nuanced needs of diverse industries. By partnering with experienced professionals, your organization can unlock the full potential of CNC technology, ensuring your products stand out in quality and innovation.

Empower Your Manufacturing with Advanced Production CNC Machining Today

If you're looking to elevate your metal fabrication projects and leverage the power of production CNC machining, consider collaborating with a trusted partner like DeepMould. With unmatched expertise and a commitment to excellence, your manufacturing goals are within reach. Invest in the future of your business by embracing the precision, efficiency, and scalability that modern CNC technology offers.